Mochini oa ho Tlatsa Oli o Iketselitsoeng oa Digital Weight

Tlhaloso

Tlhaloso

Ho tlatsa lihlahisoa tsa oli, ho kenyelletsa oli e jeoang le oli ea indasteri.Oli e jeoang ke indasteri ea litšiea tsa moruo oa naha, ke e 'ngoe ea lijo tse ka sehloohong bophelong ba rona ba letsatsi le letsatsi, joalo ka oli ea peanut, oli ea palema, oli e tsoakiloeng joalo-joalo.Oli ea indasteri haholo-holo e tlotsa oli, maemong a phahameng a boiketsetso ba indasteri kajeno, mefuta eohle ea lisebelisoa tsa mochini e ke ke ea sebetsa ntle le lubrication, mefuta e mengata haholo ea ts'ebeliso.

Ho tlatsoa ha lihlahisoa tsa oli ho hloka ho nepahala ho tlatsa ho phahameng le maemo a bohloeki, ao ho leng bonolo ho khomarela holim'a likarolo le ho baka ho rotha.Bakeng sa ho rarolla mathata ana, mochini o tlatsang oli oa GEM ha o tiise litlhoko tsa ho tlatsa feela, empa o boetse o ntlafatsa mathata a ho lutla habonolo.

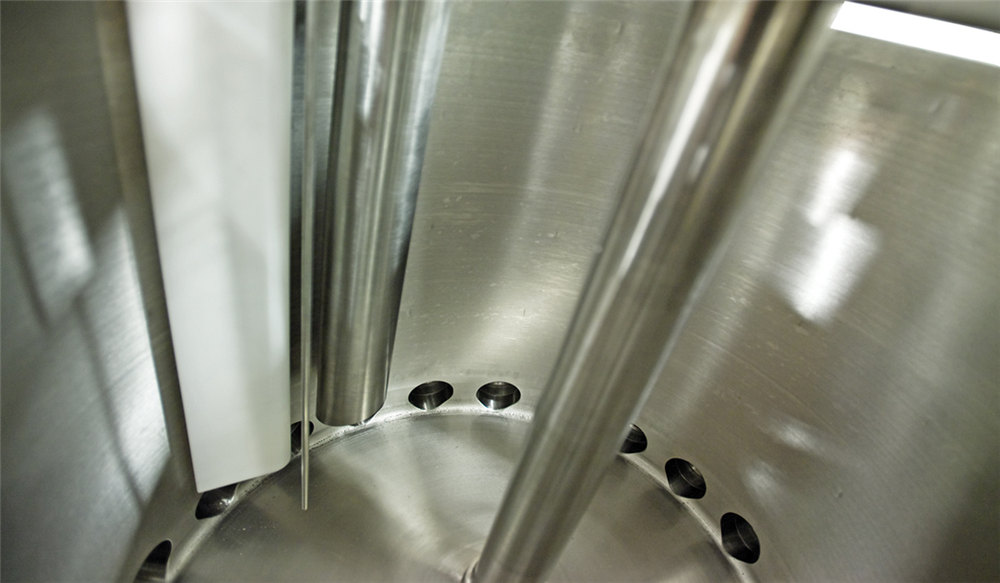

Ka lebaka la viscosity e batlang e phahame ea lihlahisoa tsa oli, ts'ebeliso ea li-valve tse tloaelehileng tsa mochini li tla baka tšitiso ea phala e khutlang, ka hona mochini o tlatsang oli hangata o sebelisa mokhoa oa ho tlatsa oa plunger.Molao-motheo oa mokhoa oa ho tlatsa li-plunger ke hore lisebelisoa tse ka har'a silinda ea ho lekanya, silinda ea ho tlatsa, ho tlatsa botlolo lijana tse tharo li lula li fetoha, li phalla.'Mele oa valve o lekana le valve ea litsela tse tharo.Ha valve e koetsoe, cylinder le cylinder li kopantsoe, 'me thepa e kenngoa ka piston ka piston.Ho otla ha piston ho lekanya boholo ba thepa e ntseng e monya, ka hona ho khetholla boholo ba thepa e tlatsitsoeng.Ha valve e buloa, silinda le botlolo li hokahane, 'me thepa e kentsoeng ka har'a silinda e hatelloa ka botlolong ho phethela ts'ebetso ea ho tlatsa bongata.Kaha matla a ho tlatsa a ka fetoloa ka ho lokisa piston stroke, ho bonolo ho tlatsa libotlolo tsa bokhoni bo fapaneng.Ho phaella moo, karolo e laolang piston e ka nkeloa sebaka ke servo drive, e etsang hore ho tlatsoa ho nepahetse le bokhoni bo loketseng haholoanyane.

Ntle le ho tlatsa li-plunger, mechini e mengata ea ho tlatsa oli e sebelisa theknoloji ea ho tlatsa boima.Ka mor'a hore boima bo se nang letho ba setshelo bo khethoe, valve ea ho tlatsa e buloa ha botlolo e fumanoa.Nakong ea ho tlatsa, sensor ea boima e lemoha palo ea sehlahisoa se kentsoeng.Hang ha boima bo hlokahalang bo fihlile, valve e koala hang-hang.Ka mor'a nako e khutšoanyane ea ho phomola, hlahloba boima hape.Nakoana pele o fihla lebili la botlolo, valve e phahamisoa hape ho netefatsa hore botlolo e tloha mochining o hloekile.Mokhoa ona oa ho tlatsa o ka etsoa ka ts'ebetso ea othomathike ea CIP, ho hloekisa senoelo sa fake ka bohona, CIP ha e hloke ts'ebetso ea matsoho.

Likarolo tsa Sebopeho sa Theknoloji

1. Ho tlatsa ka mokhoa o tloaelehileng ho sebelisa plunger quantitative filling, ho tlatsa ho nepahala ho phahame, ho bonolo ho fetoha.Li-valve tsa ho tlatsa litekanyo tsa elektronike / electromagnetic flowmeter li sebelisoa bakeng sa lihlahisoa tse nang le litlhoko tse phahameng tsa bokhoni.Ho sa tsotelehe hore na ke mofuta ofe oa valve ea ho tlatsa e ka thibelang ho rotha ha li-valve orifice.

2. Sistimi ea taolo ea Siemens e amoheloa, e nang le bokhoni bo phahameng ba ho laola ka mokhoa o itekanetseng, likarolo tsohle tsa ts'ebetso li sebetsa ka ho feletseng, ha ho na ts'ebetso e hlokahalang ka mor'a ho qala (mohlala: lebelo la ho tlatsa le latela lebelo lohle la mohala, ho lemoha boemo ba mokelikeli, taolo ea ho noa metsi. , sistimi ea lubrication, sistimi e tsamaisang sekoaelo sa botlolo)

3. Mochine oa phetiso o amohela moralo oa modular, phetoho ea maqhubu a lebelo le se nang mohato, taolo e fapaneng ea lebelo.Koloi e na le sesebelisoa sa mafura se itokisang, se ka fanang ka oli sebakeng se seng le se seng sa lubricating ho latela tlhoko ea nako le bongata, ka lubrication e lekaneng, ts'ebetso e phahameng, lerata le tlase le bophelo bo bolelele ba ts'ebeletso.

4. Bophahamo ba thepa e ka har'a silinda ea ho tlatsa e bonoa ke probe ea elektronike, 'me taolo ea PID e koetsoeng ea PLC e tiisa boemo bo tsitsitseng ba mokelikeli le ho tlatsoa ho ka tšeptjoang.

5. Ho ea ka litlhoko tsa lihlahisoa tse fapaneng, mokhoa oa ho tlatsa le mofuta oa ho tiisa o ka bapisa ho rata.Ho na le mekhoa e fapaneng ea ho tiisa (mohlala, tšoelesa ea polasetiki, kepisi ea khoele ea polasetiki, joalo-joalo)

6. Mocha oa thepa o ka hloekisoa CIP ka ho feletseng, 'me sebaka sa mosebetsi le karolo ea ho kopana ea botlolo e ka hlatsuoa ka ho toba, e finyellang litlhoko tsa bohloeki tsa ho tlatsa;E ka sebelisoa ho latela tlhoko ea tafole e sekametseng ka lehlakore le le leng;Likopi tsa maiketsetso tsa CIP tse iketselitseng le tsona lia fumaneha.

7. Ha ho kopane pakeng tsa botlolo le valve ea ho tlatsa nakong ea ho tlatsa ho qoba tšilafalo ea sefapano.

Sebopeho

Paramethara

| Che. | Letoto la Mohlala | Thepa ea Viscosity mefuta e fapaneng ea CPS | matla | E nang le mohloli oa moea | E na le mohloli oa matla | Bophahamo ba line

| e loketseng bakeng sa mefuta ea mofuta oa botlolo |

| 01 | JH-OF-6 | 0-200 | 3kw | 5-6bar | 380V | 1000±50mm | Customized ho ea ka litlhoko tsa bareki

|

| 02 | JH-OF-8 | 0-200 | 3kw | 5-6bar | 380V | 1000±50mm | |

| 03 | JH-OF-10 | 0-200 | 3.5KW | 5-6bar | 380V | 1000±50mm | |

| 04 | JH-OF-12 | 0-200 | 3.5KW | 5-6bar | 380V | 1000±50mm | |

| 05 | JH-OF-14 | 0-200 | 4.5Kw | 5-6bar | 380V | 1000±50mm | |

| 06 | JH-OF-16 | 0-200 | 4.5Kw | 5-6bar | 380V | 1000±50mm | |

| 07 | JH-OF-20 | 0-200 | 5kw | 5-6bar | 380V | 1000±50mm |