Automatic-semi-automatic CIP Plant for Beverage System

Tlhaloso

Lisebelisoa tsa CIP li sebelisa lisebelisoa tse fapaneng tsa ho hloekisa le metsi a chesang le a batang ho hloekisa litanka tse fapaneng tsa polokelo kapa lits'ebetso tsa ho tlatsa.Thepa ea CIP e tlameha ho tlosa masalla a liminerale le likokoana-hloko, hammoho le litšila tse ling le libaktheria, 'me qetellong li bolaee le ho bolaea likokoana-hloko likarolo tsa lisebelisoa.

Ho hloekisa CIP ho sebelisoa hantle indastering ea ho ritela, lino, lijo le lik'hemik'hale, hammoho le kae kapa kae moo ho hlokahalang ho hloekisoa le ho bolaea likokoana-hloko ka botlalo, joalo ka theknoloji ea baeloji.

Mekhoa ea ho hloekisa thepa ea CIP e etsoa ho latela litlhoko tsa sebele tsa ho hloekisa tsa bareki ba fapaneng bakeng sa lihlahisoa tse fapaneng e le ho fana ka tlhoekiso ea CIP e sireletsehileng le e theko e tlaase.

Melemo le Mesebetsi

1. CIP ho hloekisa lisebelisoa tsa ts'ebetso, tsamaiso ea ho tlatsa le tanka ea polokelo

2. Moralo le tlhahiso ea motho ka mong

3. Fokotsa tšebeliso ea lik'hemik'hale

4. Fokotsa tšebeliso ea matla

5. Ho hloekisa ka hare ho CIP (CIP ho itlhoekisa)

6. Ts'ebetso e bonolo, litšenyehelo tse tlaase tsa tlhokomelo, bophelo bo bolelele ba tšebeletso

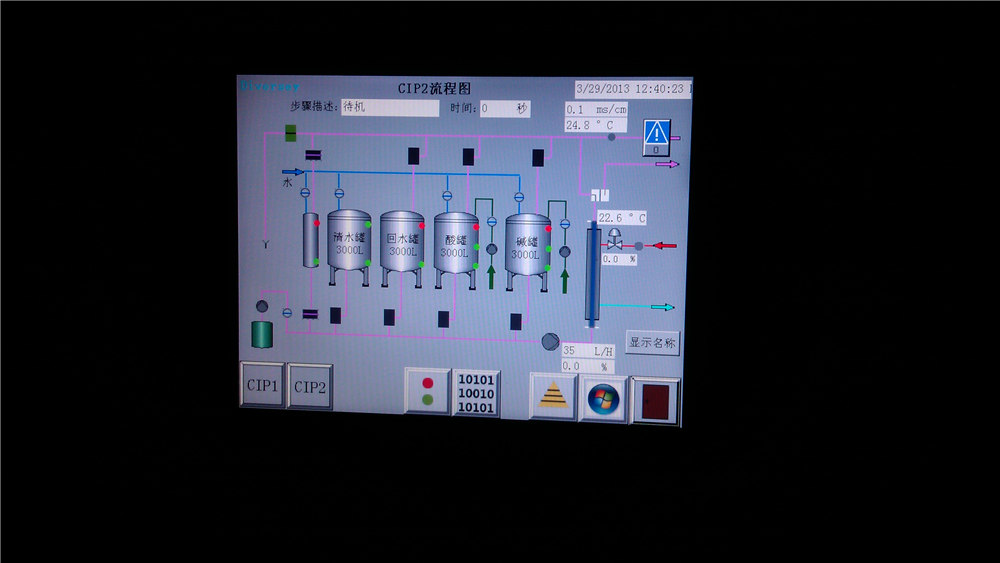

7. Ts'ebetso e ikemetseng, PLC e tloaelehileng le skrine ea ho ama

8. Boholo ba motho ka mong le meralo bakeng sa ts'ebeliso e 'ngoe le e' ngoe e ikhethileng

9. Thepa le likarolo ho latela litlhaloso tsa bareki

Tlhaloso ea Setsebi

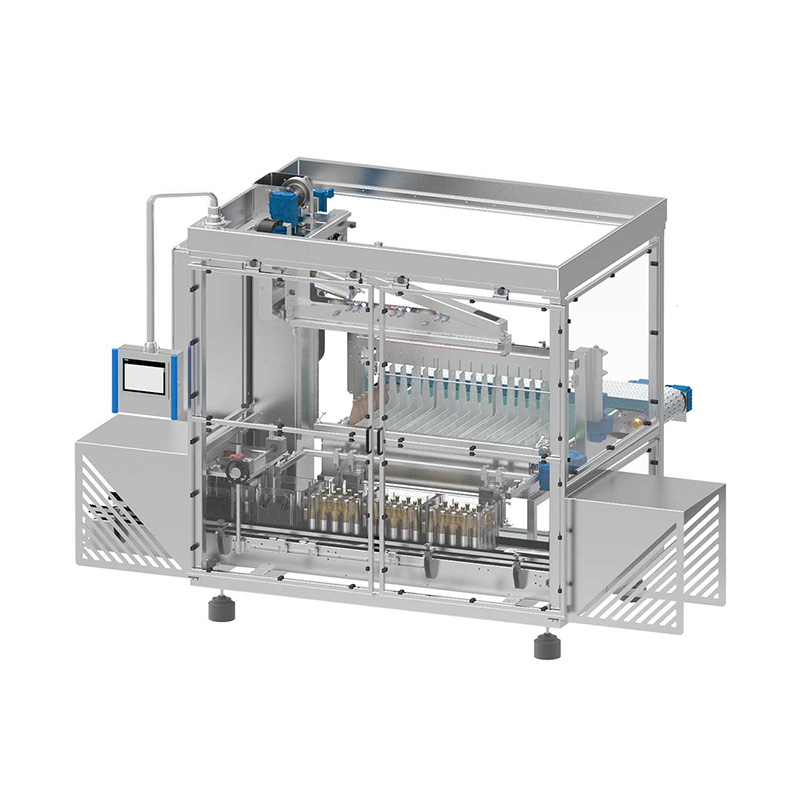

Thepa ea CIP e entsoe le ho hlomelloa ka litanka bakeng sa ho boloka li-agent tsa ho hloekisa, tse nang le loops e le 'ngoe kapa tse ngata tsa ho hloekisa, ho itšetlehile ka mosebetsi oa ho hloekisa.Litlolo tse fapaneng tsa ho hloekisa potoloho li ka bolokoa ho PLC, ts'ebetso e 'ngoe le e' ngoe ea ho hloekisa e sebetsa ka boiketsetso.

Loop e 'ngoe le e' ngoe ea CIP e laola li-valve ka nako ea 'nete ho ipapisitse le conductivity e lekantsoeng, mocheso le sekhahla sa phallo.Ka thekenoloji e ntlafalitsoeng ea ts'ebetso, ho kopanngoa ha lisebelisoa tse fapaneng tsa ho hloekisa kapa ntho leha e le efe ea ho hloekisa ho metsi a hloekileng kapa tšilafalo ea sehlahisoa ho thibeloa.E etselitsoe litekanyetso tse phahameng tsa bohloeki, lisebelisoa tsohle tsa ho hloekisa tse sebelisoang hangata liindastering tsa lino le lik'hemik'hale tsa meriana li ka sebelisoa bakeng sa ho hloekisa CIP.Sehlopha sa CIP se na le mekhoa ea ho hloekisa ka hare le li-plumbing tse tsamaellanang.

Litlhaloso tsa Tekheniki

Bokhoni ba 10 ~ 300 m3 / h

Ho futhumatsa mouoane o mahareng kapa metsi a chesang

Bophahamo ba tanka ea CIP bo ka fihla ho 40 m³