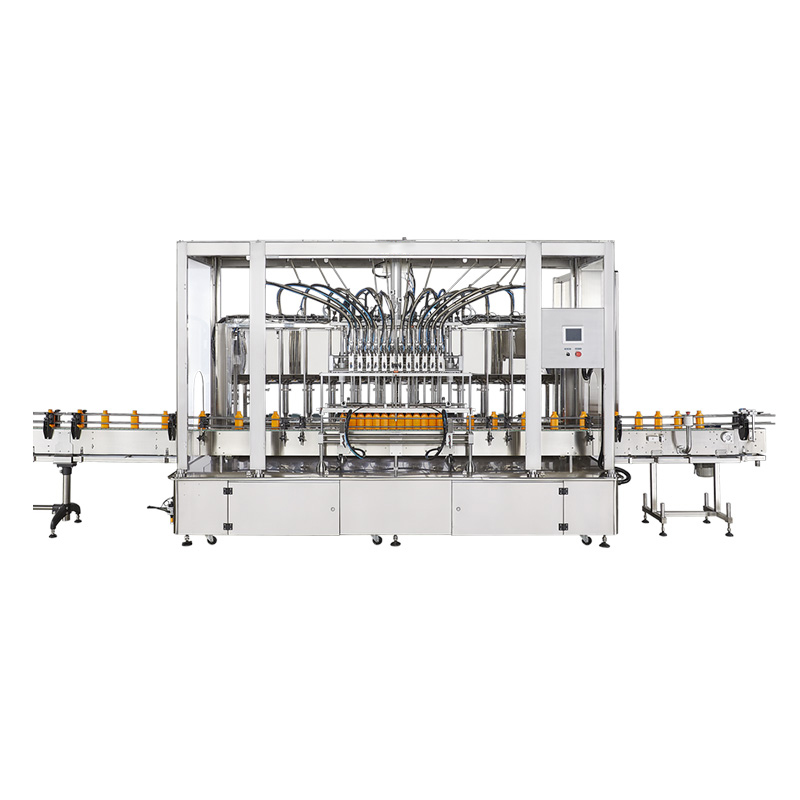

Mochini oa Pasteurization / Mochini o Mofuthu oa Botlolo / Mochini oa Botlolo o batang

Tlhaloso

Mochini oa sterilization ke o mong oa mechini ea bohlokoa moleng oa tlhahiso ea biri.Mosebetsi oa eona o ka sehloohong ke ho bolaea tomoso ka biri le ho lelefatsa bophelo ba sethala sa biri.Lenane la ho lekanya phello ea bactericidal ke boleng ba PU, 'me boleng ba PU bo tla ama tatso ea biri ka kotloloho.

Ho phaella ho sterilization, mohlala o loketse bakeng sa sterilization le pholileng ea veine, lero la litholoana le lino tse matla, hammoho le libotlolo tse futhumetseng tsa lino tse nang le carbonate.Re tla ntlafatsa moralo ho latela sehlahisoa sa moreki le bokhoni ba tlhahiso, mocheso oa sterilization, nako ea ho koala, mocheso oa kabo le nako ea ho pholisa.

Sebopeho se ka Sehloohong

Sebopeho se seholo sa mochine se entsoe ka foreimi ea kotopo le tanka e ka tlaase.Boholo ba thepa ea eona e entsoe ka tšepe e sa hloekang.Foreime ea kotopo e entsoe ka mefuta e meraro: monyako, bohareng le phallo, e ikarabellang bakeng sa ho tsamaisa le ho fafatsa veine ea botlolo.Tanka e ka tlase ke mohaho o kopantsoeng, o sebelisoang haholo ho fetola le ho aba metsi a fafatsang sebakeng se seng le se seng sa mocheso, e le ho finyella litlhoko tsa ho sebetsa ka mocheso o lekaneng oa metsi le bongata.

1. Karolo ea Frame:

Moralo oa foreimi o amohela moralo oa modular, o arotsoeng ka mefuta e meraro: monyako, bohareng le ho tsoa.Sebopeho sa bohareng se entsoe ka mokhoa o ts'oanang oa sebopeho, se loketseng bakeng sa moralo, tlhahiso le kopano.The outlet e na le enjene ho khanna motsamao oa marangrang a ketane.Marang-rang a ketane a amohela tšepe e sa hloekang ea setso ea sterilizer, 'me e eketsa poleiti ea lehlakore ho thibela ho kheloha, e le hore ts'ebetso e tsitsa, sekhahla sa ho hloleha se fokotsehe le ho feta.Sistimi ea ho fafatsa e nka sefafatsi sa lesoba le kaholimo, metsi a tšoana, sekoaelo sa botlolo ntle le sebaka se shoeleng, ho bonolo ho se hloekisa.Sekoahelo se ka holimo ke metsi a koaletsoeng ho thibela mouoane o mongata oa metsi ho tsoa.Mahlakore ka bobeli a foreimi a fanoe ka mamati a mahlakoreng bakeng sa ho shebella le ho hlokomela.

2. Tanka ea Metsi:

Mochine ona o sebelisa moralo o ka tlase oa tanka ea metsi.Bokahare ba tanka ea metsi bo arotsoe haholo ka tanka e nyane ea metsi le tanka ea buffer likarolo tse peli: tanka e nyane ea metsi e arotsoe likarolo tse 10, ka ho latellana ho tsamaellana le pokello le phepelo ea libaka tse 10 tsa mocheso oa metsi a spray;Tanka ea buffer e arotsoe ka likarolo tse tharo -- tanka ea buffer e batang, tanka ea buffer e chesang le tanka ea pre-buffer, tse sebelisetsoang ho boloka le ho fana ka metsi ka mocheso o fapaneng ka ho latellana.Tanka e batang ea buffer le tanka ea pre-buffer li hokahantsoe ka peipi ea ho leka-lekana, 'me tanka e chesang e chesang le tanka ea pre-buffer le tsona li ka tlatsetsa metsi ho tse ling, ho etsa bonnete ba ho leka-lekana ha metsi a tanka ka 'ngoe.Nakong ea ts'ebetso, metsi a ka tanka e nyenyane ea metsi sebakeng se seng le se seng sa mocheso a sebelisetsoa ho fafatsa sebakeng se seng le se seng sa mocheso, 'me metsi a ka tanka e nyenyane ea metsi a bokelloa' me a tlatsoe 'me a phallele tanka e tsamaisanang le eona bakeng sa polokelo.Metsi a chesang a ka tankeng e chesang haholo a fana ka mocheso oa metsi a fafatsang sebakeng se seng le se seng sa mocheso, le ka V-valve ea pneumatic e nang le ts'ebetso ea PID ho lokisa karolelano ea motsoako oa metsi a chesang le a batang ho etsa hore metsi a fafatse a fihle ho mocheso o sebetsang. ;Metsi a batang a ka tankeng e batang e batang a sebelisoa haholo ho fana ka pholiso ea metsi a batang le ho lokisa mocheso oa metsi a fafatsang libakeng tse futhumatsang le tse pholileng ha boleng ba PU bo laoloa.

Tanka ea metsi e entsoe ka othomathike ho kenyelletsa sesebelisoa sa khalase se robehileng, ka har'a metsi a fafatsang ka tanka pele ho etsoa moralo oa letlooeng la ketane ho tloha hloohong ho ea mohatleng, ts'ebetso ea othomathiki ea nakoana ho tšoara khalase e robehileng e hlahisoang ke botlolo e robehileng le ho tsoa. ea mochine, thibela khalase e robehileng ka tanka ea metsi, eseng feela ho sireletsa valve le pompo ea metsi le likarolo tse ling, empa hape le ho ntlafatsa tekanyo ea ho iketsetsa mochine.

Likaroloana

1. Mochini oohle o entsoe ka tšepe e sa hloekang, 'me letlooa la ketane le entsoe ka letlooa la polasetiki le hanyetsanang le mocheso o phahameng (ho ka khethoa ka ntle kapa ka malapeng).

2. Koloi e kholo e tsamaisoa ke torque e kholo le ho fokotsa lebelo le tlaase, 'me mochine o ka sehloohong le tsamaiso ea ho tsamaisa botlolo ea ka hare le ka ntle e laoloa ke mochine oa maqhubu, o nang le matla a fokolang a matla, a tsitsitseng, a sireletsehileng le a ts'ebetso e ka tšeptjoang.

3. Sisteme ea taolo ea mocheso e entsoe ka mochini o futhumatsang mocheso, sensor ea mocheso, taolo ea mocheso, valve ea ho fokotsa khatello le valve e laolang filimi ea pneumatic, mocheso o fihla ka nepo se hlokahalang ± 1 ℃, ho netefatsa boleng ba sterilization.

4. Mochine o arotsoe ka libaka tse tšeletseng kapa tse robeli tse fapaneng tsa mocheso, tse nang le tsamaiso e ikemetseng ea metsi a potolohang.Metsi a phallang a bokelloa 'me a sebelisoa hape ka mochine o futhumatsang mocheso, e leng ho fokotsang haholo tšebeliso ea metsi le tšebeliso ea mouoane ea sterilizer.

5. Nozzle holim'a pipe ea spray e amohela sebopeho se secha sa tšepe e sa hloekang, e le hore metsi a be le sekhele se nang le moholi oa moholi, phello ea ho futhumatsa e ntle, ha ho na mocheso o shoeleng Angle, phello ea ho futhumatsa e tšoana, e le ho etsa bonnete ba hore sterilization. phello ea botlolo ka 'ngoe.